|

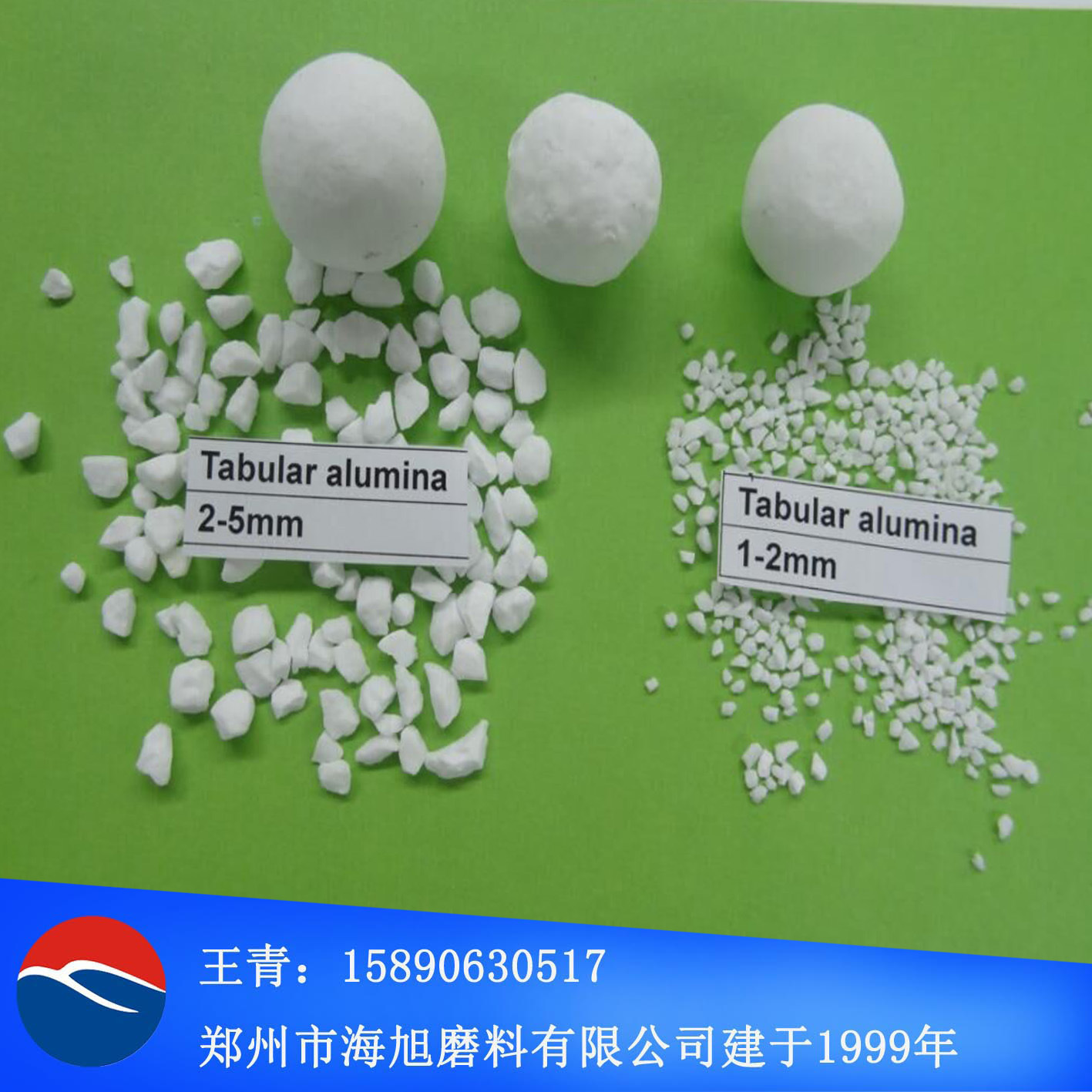

板狀剛玉段砂 0-0.5mm,0-1mm,1-2mm,2-3mm,2-5mm,3-5mm,5-8mm

|

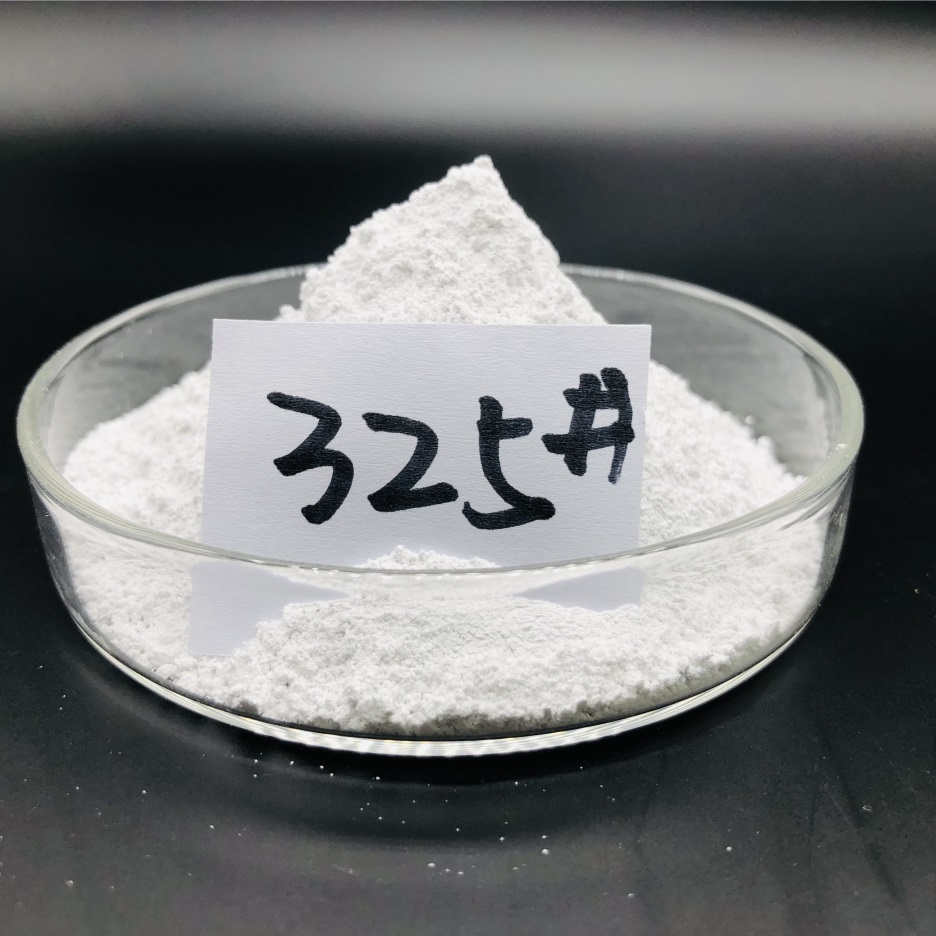

板狀剛玉粉tabular alumina powder 常用板狀剛玉細粉型號: 325#,320#-0,200#-0,150#-0,100#-0

|

海旭板狀剛玉,氧化鋁經配料、粉磨和成型后,在略低于其熔點的溫條件下燒結完全的再結晶α- Al2O3。

Description:

Haixu tabular alumina is made of Al2O3, after ingredients, grinding and forming, smelting in high temperature furnace turned to α- Al2O3.

板狀剛玉理化指標:

|

型號 Style

|

化學成分chemical index |

物理指標 physical index |

|||||

|

Al2O3% |

SiO2% |

Fe2O3% |

Na2O % |

體積密度 Volume density (g/cm3) |

吸水率 water absorption |

顯氣孔率 apparent porosity |

|

|

0-1mm 1-3mm 3-5mm 5-8mm |

99.2 min |

0.1 max |

0.1 max |

0.4 max |

3.5 |

1.5 |

5max |

|

200#-0 320#-0 325# |

99 min |

0.15 max |

0.1 max |

0.4 max |

3.45 |

2.0 |

6max

|

板狀剛玉特性:

板狀剛玉具有良好的加熱體積溫度性和良好的抗熱震能力。其晶體呈平板狀交錯排列,增加了顆粒的機械強度;晶內和晶間以分布均勻的閉氣孔為主,體積密度高,顯氣孔和吸水率低,減少了再制品的用液量;具有高耐火度、良好的熱震穩定性、低熱收縮率和良好的熱負荷強度等的物理性能。同時,高純度避免了雜質對系統的污染,是制作耐火材料、陶瓷材料和絕緣材料的理想原料。

Production feature:

Tabular alumina has good heat resistance and good bulk temperature thermal shock capabilities. The crystal staggered plate shape, to increasing the mechanical strength of the particles; interior structure full of closed pores, high bulk density, low apparent porosity and water absorption, to reducing the amount of fluid re-use productions; With good physical properties like: high refractoriness, excellent thermal shock resistance, low shrinkage and good thermal load strength etc. Meanwhile, high-purity avoiding damage to machines. Hiaxu/Sicheng is your best choose as refractory material/ceramic material and insulating materials.

板狀剛玉應用:

板狀剛玉是一種理想的耐火材料,既可以作為骨料應用于各種鋁質耐火材料中,也可以添加到其他鋁質不定型耐火材料中。

Application:

Haixu/Sicheng tabular alumina is an ideal refractory material, either can be used in various refractory alumina, or can be add in other unshaped refractories

板狀剛玉生產流程:

1.原材料

使用60#澳洲鋁粉,加入陶瓷球磨機研磨成380#的細粉

球磨機為瓷球磨,內置瓷球的直徑是30.40.50毫米

2.制作生球

380#細粉加水后,進入成球筒制球

生球規格:直徑2.4cm min

制球時間:3小時左右

3.生球烘干

烘干設備:天然氣烘干塔

烘干時間:22小時

烘干標準:水分0.5% min

4.生球燒結

4.1燒結設備介紹

燒結設備:天然氣豎窯

燒結特點:速熱速冷

天然氣豎窯規格:

內徑1.1米

外徑2.4米

塔高20米

客服1

客服1